Recycling might feel simple once you roll the bin to the curb, but what happens next is anything but. Inside modern recycling centers, bottles, cans, cardboard and plastics move through a fast-paced, highly engineered sorting process that blends human skill with advanced technology. From the early days of workers hand-picking materials on conveyor belts to today’s AI-powered robots and optical scanners, the way recyclables are sorted has evolved dramatically. Understanding how recycling is sorted not only demystifies the system but shows why putting the right things in the bin matters.

Why Proper Sorting Matters

Sorting is a key step in the recycling process. It transforms a messy pile of recyclables into usable raw materials, helping recycling programs succeed and keeping more waste out of landfills.

At a single-stream recycling center, proper sorting is especially important because it determines how much material can actually be recycled and the quality of the recycled products. While single-stream recycling allows for all recyclables to be placed in one bin, once they arrive at the facility, they must be separated by type — paper, plastics, metals and glass. Proper sorting matters for several reasons.

- Prevents contamination: If different materials get mixed together, entire batches can be ruined, making them unrecyclable.

- Protects equipment: Certain items, like broken glass or batteries, can damage sorting machines or pose safety hazards to workers if not properly separated.

- Improves efficiency: Well-sorted materials move faster through mechanical and manual sorting processes, reducing labor and operational costs.

- Ensures higher-quality recycled materials: Clean and properly sorted recyclables are more valuable to manufacturers. Contaminated or mixed materials often end up being discarded.

The Evolution of Recycling

Before the rise of advanced technology, recycling centers relied heavily on human labor. Workers stood along conveyor belts, carefully pulling out cardboard, paper, cans and bottles while removing plastic bags, trash and other contaminants like food waste, diapers or hoses. They sorted materials into designated bins or chutes, ensuring recyclables were separated for processing. This hands-on approach still exists in many smaller or rural facilities. Manual sorting faces several challenges.

- Slow Speed: Workers can sort only 20–40 items per minute.

- Physically Demanding: The work was exhausting and repetitive.

- Hazardous: Workers faced sharp objects, needles or biological waste.

- Hard to Staff: Hiring and retaining workers was difficult.

- Inconsistent Quality: Fatigue could reduce accuracy over long shifts.

Beginning in the 1990s and accelerating through the 2000s, automation transformed the way recycling facilities operate. Optical sorters introduced near-infrared sensors that could instantly identify different types of plastics and paper, while advanced screens and ballistic separators improved separation by shape and weight. In recent years, robotics and AI systems have pushed sorting even further, recognizing items by material, shape and even brand. Together, these technologies have:

- Increased material purity

- Boosted recovery rates

- Improved efficiency

- Heightened worker safety

- Strengthened the overall profitability of recycling programs

How Recycling Is Sorted at Modern Recycling Facilities

To better understand how recycling is sorted, it helps to look at the three types of technologies working together behind the scenes.

Screens and Ballistic Separators

Screens and ballistic separators make it easier for recycling facilities to sort materials right from the start. Screens act like a filter, letting smaller or flat items (such as paper and cardboard) fall through while moving larger items (such as bottles and cans) along to the next step.

Ballistic separators use a gentle shaking motion to separate materials by shape and weight. Flat, light items like paper and film glide forward, round items like bottles and cans roll down, and tiny pieces drop through small holes for separate collection. By dividing the mixed recyclables into simpler groups, these machines make it easier for other equipment to sort everything more accurately later on.

Robotic Sorting Arms

Modern robotics sorting machines use computer vision, AI and robotic arms to identify and separate recyclables at high speed, giving robots the ability to “see,” recognize and pick items accurately on a moving conveyor belt. Here’s how the process works.

- Cameras Scan the Conveyor Belt: High-resolution cameras continuously capture video of materials moving on the conveyor. These images are sent to AI software for real-time analysis.

- AI Identifies Each Item: The AI has been trained on millions of images of recyclables and can quickly (within milliseconds) recognize different types of plastic, paper, metals and glass.

- Software Determines What to Pick: The system is programmed with facility priorities, such as removing contamination, sorting by material or color or collecting high-value items like aluminum cans. The AI calculates the exact position, speed, pick point and robotic arm path in real time.

- Robotic Arms Pick and Place Items: Using vacuum suction cups or grippers, robotic arms grab each item and place it into the correct chute or bunker. The system can make multiple picks per second, handle small or oddly shaped items, adjust instantly if items shift on the conveyor and operate continuously without fatigue.

- Continuous Learning and Improvement: The AI software continuously learns and adapts, improving its ability to identify new packaging, recognizes dirty or damaged items and adjusts to seasonal changes in the types of recyclables processed.

AI-Powered Optical Sorters

Optical sorters use cameras, sensors and timed air jets to automatically separate different materials on a conveyor, helping recycling centers sort more accurately and quickly. The general steps are:

- Material Is Spread Out on a Fast Conveyor: Incoming recyclables are evenly distributed into a single layer so each item can be scanned individually.

- High-Speed Optical Sensors Scan Each Item: Visual and nearinfrared sensors capture detailed data about color, shape and composition, allowing the system to distinguish plastics, paper, metals and other materials.

- The Software Classifies Materials in Real Time: The sorting software uses sensor data to identify what each object is, whether it should be kept or rejected and precisely where it is on the belt.

- Air Jets Remove or Redirect Items: At the right moment, bursts of air push targeted materials into the appropriate collection chutes while nonejected items fall into a different stream.

- Sorted Streams are Collected: The result can include multiple output streams such as clear plastics, colored plastics, paper and metals depending on how the system is set up.

FAQs: Modern Recycling Technologies

Q: How does AI technology help in recycling?

A: AI-powered systems can “see” and identify materials like plastics, metals and paper, guiding robots or machines to sort them more accurately than humans alone.

Q: What do recycling robots do?

A: Robots pick and separate items from a mixed stream, often using AI vision to recognize materials and sort them quickly and precisely.

Q: Why combine traditional machines with AI and robots?

A: Machines like screens and separators handle bulk sorting efficiently, while AI and robots refine the process, catching items machines might miss and improving overall recycling quality.

Q: Why isn’t human sorting always ideal?

A: Human sorters face dangers such as broken glass, sharp metal or hazardous materials, and fatigue can lead to mistakes. Machines and robots help reduce these risks while increasing efficiency.

Q: Can these technologies handle all recyclables?

A: They handle many common materials, including paper, cardboard, plastics and metals but hazardous items or electronics still need special processing.

Q: Are AI and robots making recycling faster?

A: Yes. Automation speeds up sorting, reduces errors and allows facilities to process larger volumes of recyclables safely.

Q: Do these technologies reduce waste going to landfills?

A: Definitely. Better sorting means more materials are recycled instead of being thrown away.

Q: What can consumers do to help recycling work better?

A: Rinse containers to reduce contamination, separate recyclables according to local guidelines and avoid putting non-recyclable items in the bin, which slows sorting and can damage machines.

Q: Will robots replace human workers in recycling facilities?

A: Not completely. Humans are still needed for maintenance, quality checks and handling items machines can’t safely process.

Q: What’s the future of recycling technology?

A: Expect smarter AI, faster robots and more integrated systems that can sort more materials with higher accuracy, creating a safer and more efficient recycling process.

Tips to Make Your Recycling Count

Here are some practical tips consumers can follow to support these recycling technologies and improve how recycling is sorted in a single-stream system.

- Know your local rules: Recycling programs vary by city, so check what materials your curbside service accepts before tossing them in the bin. This helps reduce contamination, which improves processing and recovery rates.

- Keep recyclables clean: Rinse out bottles, cans and other containers and shake off excess moisture before recycling. Food residue and wet materials can spoil entire batches of recyclables, making them harder for facilities to process.

- Avoid contamination: Don’t include items such as plastic bags, greasy pizza boxes or hazardous materials in your curbside bin. Many of these require special drop-off locations and can jam or damage sorting equipment.

- Flatten boxes: Break down cardboard boxes to save space and make them easier to handle. Clear organization at home sets recycling facilities up for success.

- Use the right bins: Place recycling bins next to trash at home so recycling becomes the easier choice, and consider separate containers for paper, plastics, glass and metals if your local program suggests it.

- Educate and advocate: Share correct recycling habits with friends and family, support community recycling education programs and encourage local leaders to invest in recycling infrastructure and technology.

Why Technology and Your Recycling Habits Matter

Today’s recycling facilities use a mix of human workers, smart machines and AI-powered robots to sort materials more quickly and accurately than ever before. These technologies reduce contamination, improve safety for workers and help recover more recyclable material.

Even with advanced systems in place, recycling still depends on consumers. When items are clean, empty and recyclable, sorting technology works better and more materials can be successfully recycled. As AI and robotics continue to improve, the combination of smart technology and responsible recycling habits will shape a more efficient and sustainable future.

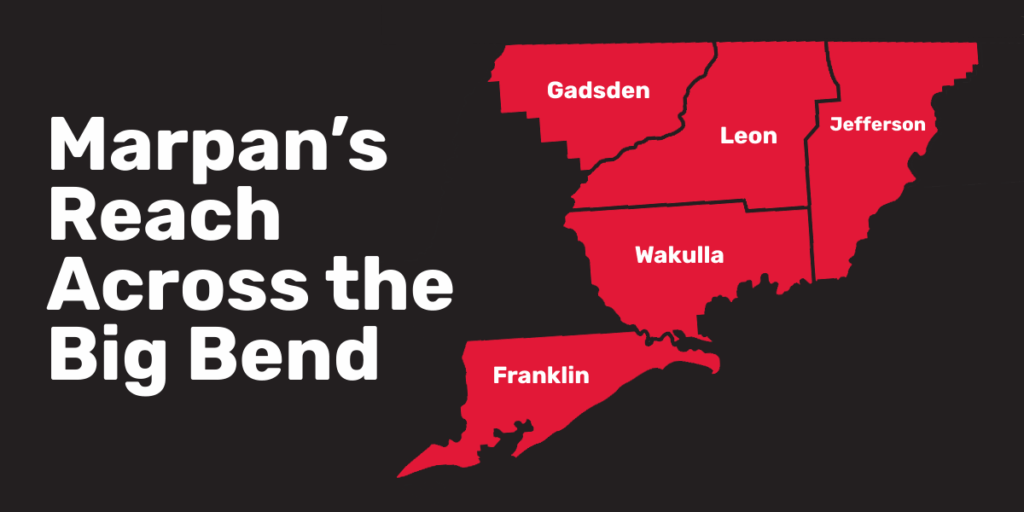

Local Leadership: Marpan’s Role in Sustainable Recycling

Marpan specializes in processing household recyclables at their state-of-the-art single-stream facility in Tallahassee, Florida. With single-stream recycling, Leon County residents no longer need to separate paper, plastic, metal and glass — everything goes into the same bin, and Marpan handles the sorting. To make recycling simple and effective, download our recycling guidelines, which provide essential rules and instructions for successful household recycling. Learn more ways to support recycling efforts in Tallahassee and North Florida by checking out our latest news.

Marpan has led Tallahassee and North Florida in debris management and processing of residential and commercial recyclable materials since 1966. Between 2008 and 2022, our recycling facility recovered more than two billion pounds of material that would have otherwise been buried in a landfill. Our partnerships, long-time commitment to recycling and state-of-the-art facilities allow us to make a difference in our community every day. For more information on how and what we recycle, explore our services.